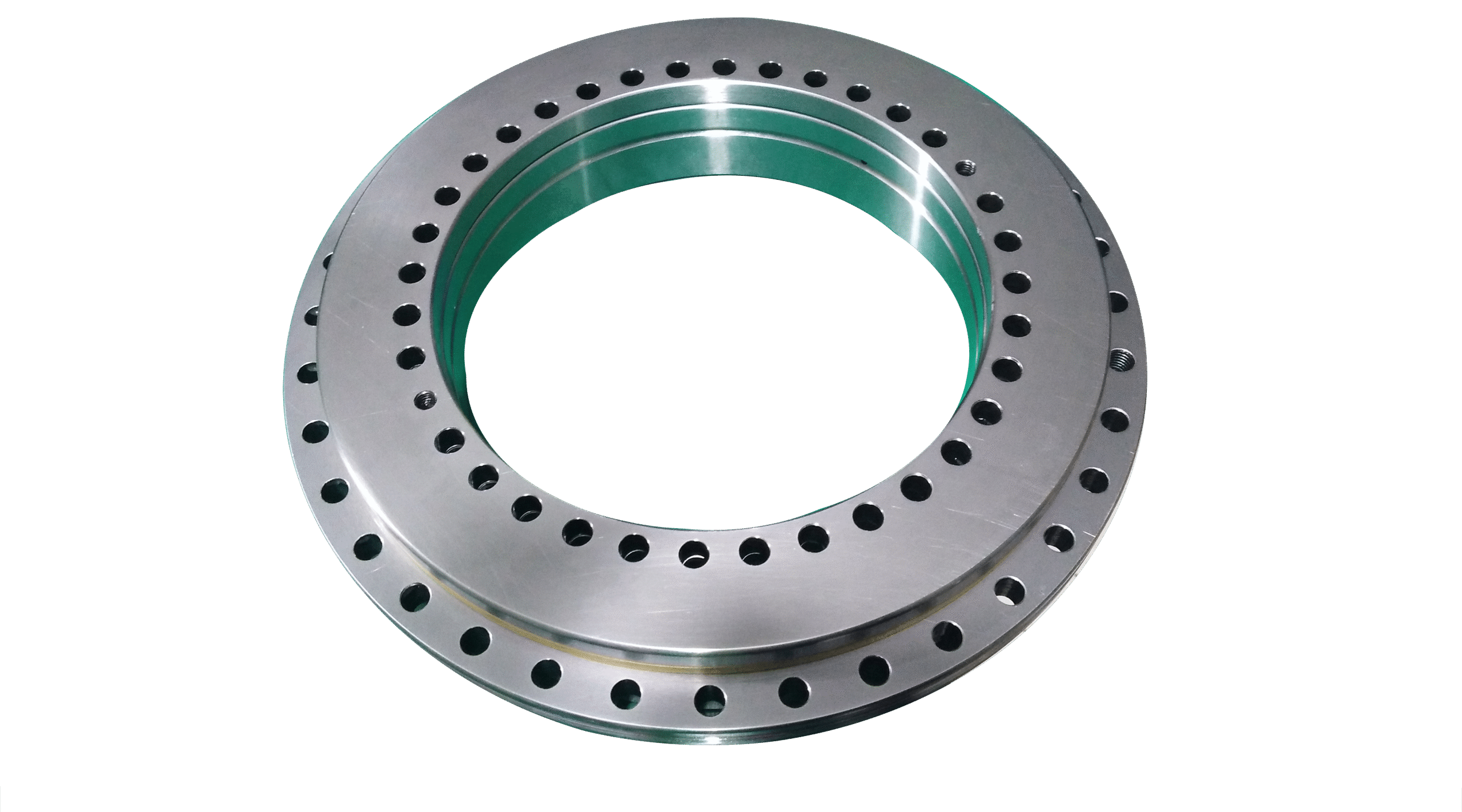

Slewing bearings, specifically the YRTC series, are critical components in a wide range of mechanical applications, serving as essential interfaces between structures and rotating elements. This article delves into the advantages, applications, installation procedures, and notable characteristics of YRTC slewing bearings, highlighting their significance in modern engineering and construction.

Advantages of YRTC Slewing Bearings

YRTC slewing bearings offer numerous benefits that make them a preferred choice for various applications. Firstly, they exhibit superior load-carrying capacity, allowing them to support extensive axial, radial, and moment loads efficiently. This characteristic is crucial in applications where high mechanical stress is a common occurrence.

Additionally, YRTC slewing bearings are designed for durability and longevity. Their robust construction typically involves high-quality materials such as alloy steel, ensuring resistance to wear and fatigue. Furthermore, these bearings are engineered to maintain operational efficiency under diverse environmental conditions, including extreme temperatures and exposure to moisture, which can accelerate wear in substandard bearings.

Another notable advantage is the seamless rotation they provide. YRTC bearings are designed with a precision manufacturing process that minimizes friction and maximizes smooth operation. This smooth rotation not only enhances the performance of the machinery but also contributes to energy savings and reduced operational costs.

Applications of YRTC Slewing Bearings

YRTC slewing bearings are versatile components employed across various industries. Their applications can be found in the construction sector, particularly in cranes, excavators, and drilling machines. The ability to support heavy loads while allowing for fluid movement makes these bearings indispensable in equipment designed for heavy lifting and precise positioning.

In the renewable energy industry, YRTC slewing bearings are commonly used in wind turbines, where they facilitate the rotation of the turbine blades to optimize energy capture. Their robust nature, combined with the capability to withstand harsh environmental conditions, makes them ideal for such applications.

Moreover, the automotive sector utilizes YRTC slewing bearings in applications like automotive lifts and turntables, where reliable rotation is essential. Additionally, they find their place in the marine industry for radar systems and equipment that require angular movement without compromising stability.

Installation of YRTC Slewing Bearings

The installation of YRTC slewing bearings requires careful attention to detail to ensure optimal performance and longevity. It is essential to start with a clean and prepared mounting surface, free from debris or contaminants that could interfere with operation. The mounting surface should be leveled to prevent misalignment, which is crucial for the bearing’s functionality.

Prior to installation, it is advisable to inspect the bearing for any signs of damage or defects. Proper lubrication is a key step; the bearings should be adequately greased or oiled according to the manufacturer’s specifications to minimize friction and wear.

During the installation process, even distribution of bolts is vital. Bolts should be tightened gradually in a crisscross pattern to ensure uniform pressure across the bearing. This careful method reduces the risk of deformation and enhances the bearing’s performance. Once installed, a functional test should be conducted to confirm proper operation.

Features of YRTC Slewing Bearings

YRTC slewing bearings are characterized by several key features that highlight their engineering excellence. One of the standout features is their design, which often includes an integral raceway and roller element structure. This configuration allows for load distribution across a larger surface area, improving stability and performance.

Additionally, YRTC bearings often come with customized designs to meet specific operational requirements. This flexibility ensures that clients can obtain bearings tailored to their unique applications, enhancing performance further.

Sealing systems in YRTC slewing bearings are another significant feature. High-quality seals prevent the ingress of contaminants while retaining lubrication, crucial for maintaining optimal operational conditions. Furthermore, many YRTC bearings are designed for easy maintenance, allowing users to monitor and replace lubricants without extensive downtime.

In conclusion, YRTC slewing bearings provide a compelling combination of durability, versatility, and robust performance across various applications. Understanding their advantages, installation methods, and key features will empower engineers and operators to make informed decisions in selecting the right slewing bearings for their projects, ultimately enhancing operational efficiency and equipment longevity.