Introduction

Slewing bearings, particularly YRT slewing bearings, are essential components in various machinery and equipment where precise rotational movement is required. Their unique design and functionality make them suitable for a wide range of applications, especially in heavy machinery, automation, and robotics. This article delves into the advantages of YRT slewing bearings, their applications across different industries, the installation process, and their distinctive features.

Advantages of YRT Slewing Bearings

- High Load Capacity: YRT slewing bearings are designed to withstand significant radial, axial, and moment loads. This capability allows them to be utilized in heavy-duty applications without compromising performance.

- Precision Movement: The design of YRT bearings enables high precision in rotation. This is particularly important in applications where exact positioning is critical, such as in robotics and positioning systems.

- Durability and Longevity: Constructed from high-quality materials, YRT bearings exhibit excellent wear resistance. Their robust design offers extended service life, reducing the frequency of replacements and maintenance.

- Ease of Maintenance: YRT bearings typically require minimal maintenance, contributing to lower operational costs. Their design allows for easy access during service and inspections.

- Versatile Design: The ability to customize YRT slewing bearings according to specific application requirements makes them a flexible solution for various engineering challenges.

Applications of YRT Slewing Bearings

YRT slewing bearings find applications across a multitude of industries, including:

- Construction Equipment: In cranes and excavators, YRT bearings facilitate smooth and controlled rotation, crucial for lifting and moving heavy loads.

- Wind Turbines: These bearings are employed in the rotor and yaw mechanisms, enabling efficient tracking of wind direction and optimizing energy capture.

- Robotics: In robotic arms and automated machinery, YRT bearings offer precise rotational movement and positioning, essential for intricate tasks.

- Marine Applications: YRT bearings are utilized in turntables, marine cranes, and other equipment where rotational movement is required under variable load conditions.

- Medical Equipment: In imaging devices and surgical equipment, YRT bearings enable rotation and positioning that are vital for operational accuracy and safety.

Installation of YRT Slewing Bearings

The installation of YRT slewing bearings requires careful attention to detail to ensure optimal performance. The process typically includes the following steps:

- Preparation: Before installation, it is essential to inspect the bearing and the mounting surfaces. Clean all surfaces to eliminate contaminants that could affect performance.

- Alignment: Proper alignment is crucial. The mounting surfaces should be level and accurately aligned to prevent undue stress on the bearings during operation.

- Fastening: Using the appropriate bolts or fasteners as specified by the manufacturer, securely attach the bearing to the mounting structure. Ensure that the fastening sequence follows the recommended pattern to distribute the load evenly.

- Lubrication: Apply the correct type of lubricant as prescribed, ensuring that the bearing operates smoothly and reduces friction during use.

- Final Checks: Conduct a final inspection to confirm correct installation, alignment, and fastening before putting the machinery into operation.

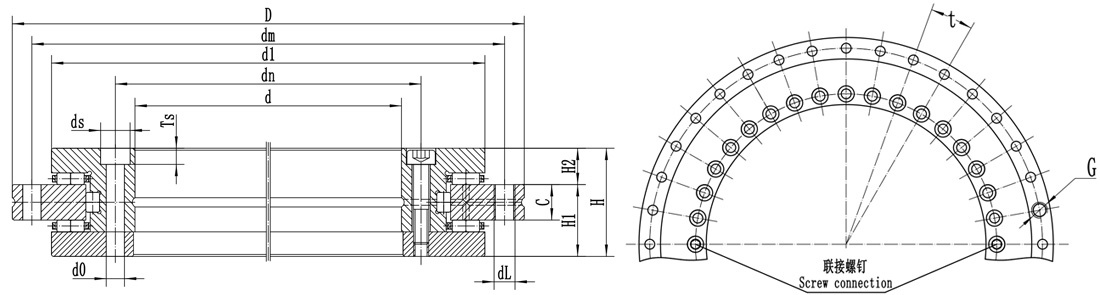

Features of YRT Slewing Bearings

YRT slewing bearings exhibit several distinctive features that set them apart from other bearing types:

- Integrated Gear Options: Many YRT bearings are available with integrated gearing for enhanced torque transmission, allowing for precise control in motion.

- Compact Design: The compact nature of YRT bearings makes them suitable for applications with space constraints, optimizing design without sacrificing performance.

- Multiple Contact Points: The design incorporates multiple contact points that improve load distribution and stability, allowing for greater performance under varying load conditions.

- Sealing Solutions: Many YRT bearings come with advanced sealing technology to protect against contaminants and retain lubrication, ensuring reliable operation in challenging environments.

- Customization: Manufacturers often offer customization options for various dimensions, load capacities, and materials, catering to specific application needs.

Conclusion

YRT slewing bearings are vital components across many industries, recognized for their high load capacity, precision, and durability. Understanding their advantages, applications, installation procedures, and key features is essential for engineers and technicians working with these specialized bearings. By leveraging the benefits of YRT slewing bearings, industries can enhance operational efficiency, safety, and reliability in their equipment and machinery.