In the realm of mechanical engineering and manufacturing, the significance of high-performance bearing systems cannot be overstated. Within this context, the SHF bearing emerges as a notable component, widely utilized for its unique features and benefits. This article aims to provide a comprehensive introduction to SHF bearings, focusing on their construction, applications, advantages, and considerations for selection.

What is an SHF Bearing?

The SHF bearing series is a type of linear bearing specifically designed for smooth, precise motion in linear motion systems. These bearings are typically made from high-quality steel or other durable materials, ensuring enhanced load capacities and longevity. The hallmark of SHF bearings is their ability to accommodate linear movements while minimizing friction, thereby facilitating higher efficiency in various applications.

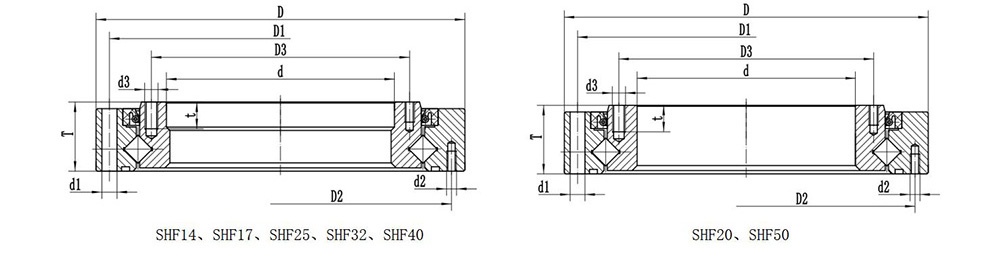

Construction of SHF Bearings

SHF bearings are primarily characterized by their robust design. The main components include:

- Outer Housing: This component provides structural integrity and serves as the mounting interface for installation.

- Linear Ball Guides: These incorporate small steel balls that allow for smooth linear motion along a rail or track. The design minimizes surface contact, leading to reduced friction.

- End Caps: Typically made from synthetic materials, these caps offer protection to the internal components from dust and debris, thus extending the lifespan of the bearing.

This meticulous construction enables SHF bearings to provide superior load handling and operational reliability across various applications.

Applications of SHF Bearings

Due to their versatility, SHF bearings find applications in numerous fields, including but not limited to:

– Automation Equipment: In automated systems, where precision and reliability are paramount, SHF bearings ensure smooth movement of robotic arms and conveyor systems.

– CNC Machines: The manufacturing industry heavily relies on SHF bearings for CNC machines, where high accuracy and low friction are critical for maintaining product quality.

– 3D Printers: In additive manufacturing, SHF bearings facilitate the linear movements of print heads, contributing to the overall quality and efficiency of the printing process.

– Medical Equipment: Devices such as MRI machines and other diagnostic tools benefit from the stability and precision that SHF bearings provide.

Advantages of SHF Bearings

The adoption of SHF bearings brings forth numerous advantages:

- Reduced Friction: The design and material selection significantly reduce friction between moving parts, enhancing overall efficiency and reducing wear.

- High Load Capacity: SHF bearings are engineered to support substantial loads, making them suitable for heavy-duty applications.

- Durability: With resistance to various environmental factors, such as dirt and moisture, SHF bearings demonstrate extended service life even in demanding conditions.

- Versatile Compatibility: These bearings can be easily integrated into existing systems, providing flexibility for engineers and designers.

Considerations for Selection

When selecting SHF bearings for a particular application, several factors should be taken into account:

– Load Requirements: Analyze the operational loads to ensure that the chosen bearing can adequately support them without compromising performance.

– Speed and Distance: Evaluate the required speed and stroke length to determine the optimal type of SHF bearing.

– Environmental Factors: Consider the operational environment, including temperature, humidity, and exposure to contaminants, as these can influence bearing performance.

Conclusion

In conclusion, SHF bearings are a critical technology that supports a wide array of applications across numerous industries. Their robust construction, coupled with the advantages of reduced friction and high load capacities, makes them an attractive choice for engineers and manufacturers. By understanding their features, applications, and selection criteria, stakeholders can make informed decisions that enhance the performance and reliability of their mechanical systems. As industries continue to evolve, the importance of advanced bearing technologies like SHF bearings will undoubtedly play a pivotal role in achieving operational excellence.