Introduction

Crossed roller bearings are specialized bearings designed for applications where space is limited, yet high performance is essential. Among various types of crossed roller bearings, the RB series stands out due to its unique design and versatile applications. This blog post will explore the distinctive features, benefits, common applications, and popular models of the RB series crossed roller bearings.

Features of RB Series Crossed Roller Bearings

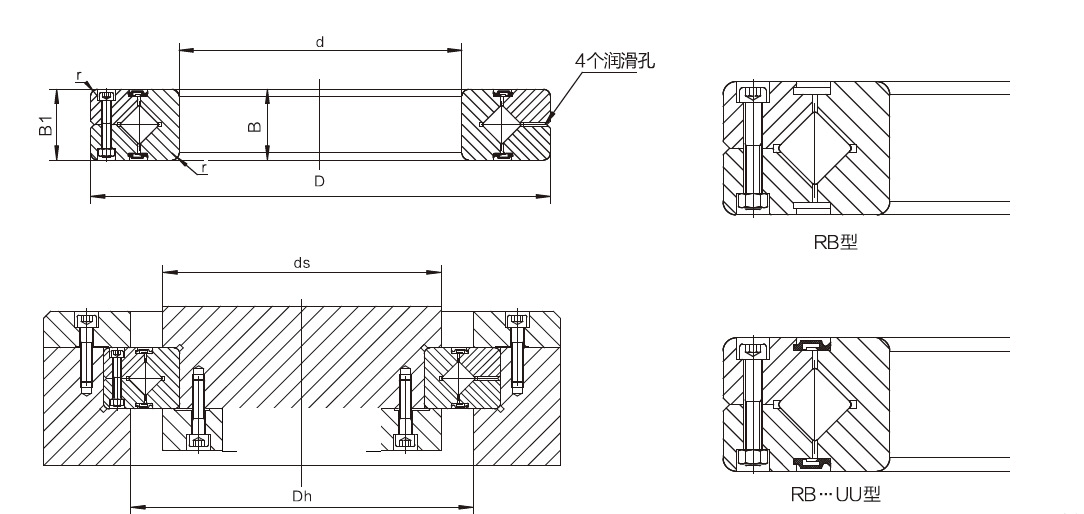

The RB series of crossed roller bearings is characterized by its innovative construction, which comprises two rings of rollers arranged in a crisscross pattern. This configuration allows the bearing to accommodate loads in multiple directions while maintaining high rigidity. Key features include:

- Compact Design: The structure of the RB series allows for a narrow axial width, making it an ideal choice for space-constrained environments.

- High Load Capacity: The crossed roller arrangement distributes loads evenly across the rollers, enabling the bearings to handle significant axial, radial, and moment loads without compromising performance.

- Precision Construction: Typically manufactured with high-grade materials, RB series bearings provide exceptional precision and durability, essential for high-speed and high-accuracy applications.

- Easy Installation: These bearings often come with integral mounting holes, simplifying installation and alignment in machinery.

- Low Friction: The design minimizes friction, resulting in smoother operation and reduced wear over time.

Advantages of RB Series Crossed Roller Bearings

The RB series offers numerous advantages that make them a preferred choice in various industries:

- High Rigidity and Stability: The crossed roller design ensures high rigidity, crucial for applications requiring precision and stability, such as CNC machinery and robotics.

- Versatility: RB series bearings are suitable for a wide range of applications, from industrial machinery to medical equipment, due to their ability to handle different load orientations.

- Reduced Maintenance: With excellent wear resistance and low friction, these bearings require less frequent maintenance, leading to reduced operational costs and improved reliability.

- Lower Noise Levels: The smooth and efficient operation of RB series bearings translates into lower noise levels, an essential consideration in many applications.

- Wide Operating Temperature Range: Being made from advanced materials allows for effective performance in a wider range of temperatures, enhancing their utility in various conditions.

Common Applications

The RB series crossed roller bearings are utilized in numerous applications across different industries, including:

– Robotics: Their compact design and high load capacity make them ideal for robotic joints and arms that require precise movements.

– CNC Machinery: The precision and stability of RB series bearings are paramount in CNC machines, where accuracy dictates the quality of workmanship.

– Medical Equipment: In devices such as MRI machines and surgical robots, the reliability and low maintenance of RB series bearings contribute to overall operational efficiency.

-Aerospace: These bearings are employed in critical aerospace components, providing the necessary performance under stringent conditions.

– Semiconductor Manufacturing: High precision is essential in this field, and the RB series bearings meet these demands admirably.

Popular Models of RB Series Crossed Roller Bearings

The RB series encompasses a variety of models to cater to different requirements. Some commonly used ones include:

- RB2008: This model features a compact size with a high load capacity, suitable for applications in automation and robotics.

- RB3010: Known for its versatility, the RB30 is widely used in CNC equipment and is designed for effective operation under moderate loads.

- RB4010: A heavier-duty model, the RB40 is often found in industries requiring robust performance, such as aerospace and heavy machinery.

- RB5013: This model is favored for precision applications, providing exceptional stability and low friction for high-speed operations.

Conclusion

The RB series crossed roller bearings represent a pinnacle of engineering design, offering a unique solution for a myriad of applications. Their compact structure, high load capacity, and versatility make them indispensable in modern industrial environments. As technology progresses and demands for precision and reliability increase, the RB series will continue to play a critical role in the development of future machinery and equipment. For anyone considering advanced bearing solutions, the RB series is undoubtedly an excellent choice that combines efficiency, durability, and precision.