Cross roller bearings play a pivotal role in various mechanical applications, providing support and stability where high precision and load capacity are paramount. Among the diverse types of cross roller bearings, the CRBS series stands out due to its unique design and versatile applications. In this blog post, we will delve into the characteristics, applications, advantages, and commonly used models of the CRBS series cross roller bearings.

Characteristics of CRBS Series Cross Roller Bearings

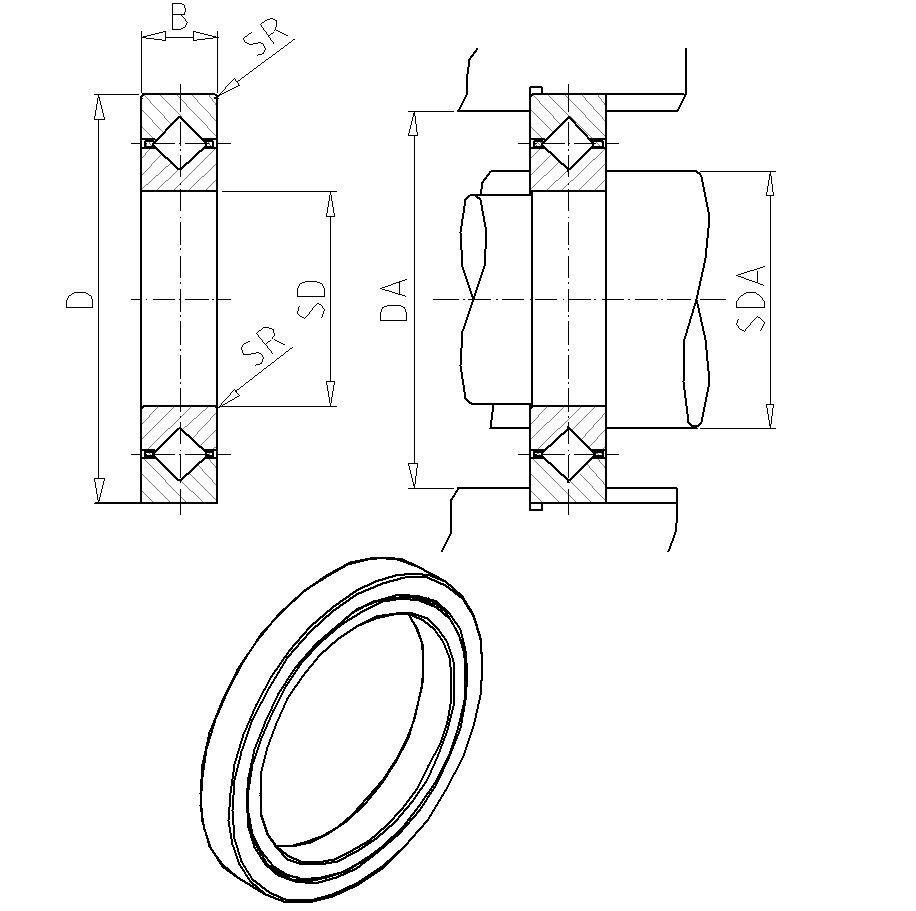

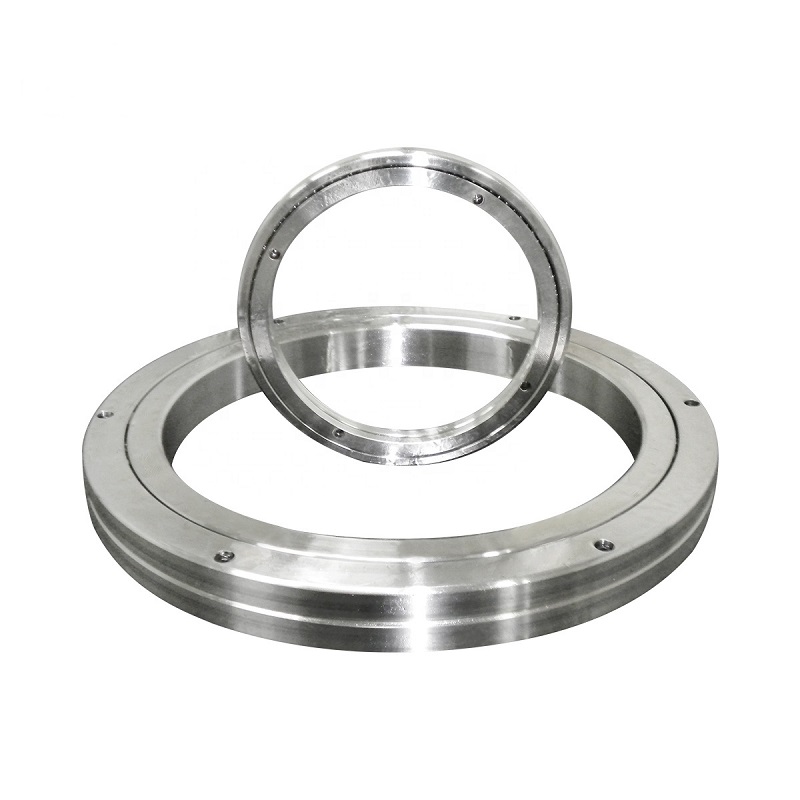

The CRBS series is distinguished by its innovative structure, which consists of alternate cylindrical rollers arranged perpendicular to each other. This configuration allows the bearing to accommodate loads in multiple directions, making it particularly effective in applications that involve radial and axial loads simultaneously. Key characteristics of the CRBS series include:

- High Load Capacity: The optimized roller design provides exceptional load bearing capabilities, allowing the bearing to handle both radial and axial loads efficiently.

- Compact Design: The relatively thin profile of the CRBS series enables space optimization in machinery, which is crucial in designs where dimensions are restricted.

- Reduced Friction: The precise design and surface finish of the rollers contribute to lower friction levels during operation, resulting in smoother performance and reduced wear on components.

- Easy Installation: Many models within the CRBS series are designed for straightforward installation, minimizing the time and effort required for integration into machinery.

Applications of CRBS Series Cross Roller Bearings

Due to their unique attributes, CRBS series cross roller bearings are used across a broad spectrum of industries and applications. Some of the prominent fields where these bearings are commonly utilized include:

- Robotics: The precision and load capacity of CRBS bearings make them ideal for robotic joints and end effectors that require high stability and repeatability.

- Medical Equipment: In the medical field, where exact positioning is crucial, CRBS series bearings are employed in imaging equipment, surgical robots, and other precision instruments.

- Machine Tools: CRBS bearings are extensively used in CNC machines and milling equipment, where they contribute to heightened accuracy and prolonged operational life.

- Industrial Automation: In automated systems that require effortless movement and positioning of components, the CRBS series provides the necessary support and friction reduction.

- Aerospace: The demanding criteria of the aerospace industry align well with the capabilities of CRBS series bearings, which are used in applications where reliability and performance are essential.

Advantages of CRBS Series Cross Roller Bearings

The CRBS series offers several advantages that set it apart from other bearing designs:

- Versatility: The ability to accommodate both radial and axial loads makes CRBS bearings suitable for various complex applications.

- Durability: Designed with high-quality materials and precise engineering, CRBS bearings exhibit exceptional durability and a long service life, reducing maintenance costs.

- Precision Engineering: The precision manufacturing of these bearings ensures optimal performance in high-speed applications, with minimal vibration and noise.

- Cost-Effective: Although CRBS bearings might require a higher initial investment, their longevity and reliability contribute to cost savings in the long run by minimizing downtime and maintenance needs.

Commonly Used Models of CRBS Series Cross Roller Bearings

The CRBS series includes various models that cater to different specifications and requirements. Some of the most commonly used models include:

- CRBS2: Known for its compact size and moderate load capacity, this model is widely used in space-critical applications.

- CRBS3: Featuring a higher load capacity than the CRBS2, this model is suitable for applications demanding additional support without compromising on dimensions.

- CRBS4: The CRBS4 model is designed for heavy-duty applications, offering enhanced durability and stability for larger machinery and equipment.

- CRBS5: This model is ideal for applications that require ultra-fine precision and is frequently found in high-technology industries.

- CRBS6: A robust model designed for extreme conditions, the CRBS6 excels in environments with high temperatures or corrosive elements, proving its versatility in demanding applications.

Conclusion

In summary, the CRBS series cross roller bearings represent a significant advancement in bearing technology, combining high load capacity, versatility, and precision into a compact package. Their wide range of applications across various industries underscores their importance in modern machine design and automation systems. As technology continues to evolve, the CRBS series will undoubtedly remain a key player in enhancing performance and reliability in precision engineering. Whether in robotics, medical devices, or industrial machinery, the CRBS series cross roller bearings are poised to meet the challenges of tomorrow’s engineering demands.