Cross roller bearings are a pivotal component in various engineering applications, offering superior performance and reliability. Among the different types of cross roller bearings, the CRB and CRBC series stand out due to their unique design and operational advantages. In this blog, we will explore the characteristics, applications, benefits, and common models of these bearings.

Characteristics of CRB and CRBC Series

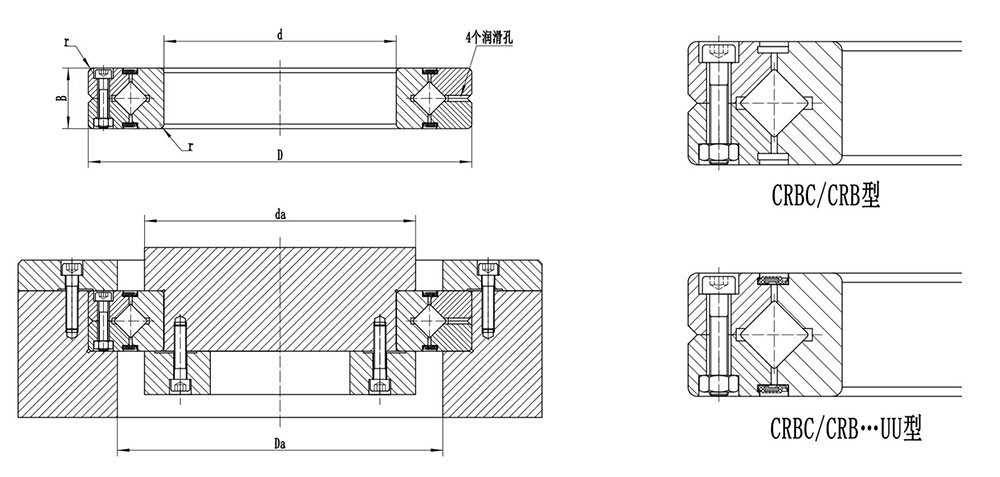

The CRB series is characterized by its structure that utilizes alternating rollers, which are arranged perpendicularly to each other. This design allows for high load capacity and rigidity, making them ideal for heavy-duty applications. The CRBC series, on the other hand, integrates a built-in inner ring and is designed for applications where reduced space is a critical factor.

Both series share several fundamental characteristics:

– Compact Design: They offer a compact structure while maintaining high load-carrying capacity.

– High Precision: The design ensures reduced friction and increased accuracy in motion, making them suitable for precision machinery.

– Enhanced Load Distribution: The perpendicular arrangement of rollers helps in distributing loads evenly, reducing stress concentrations.

Applications of CRB and CRBC Series

Given their robust design and high performance, the CRB and CRBC series are widely employed across various industries. Common applications include:

- Robotics: In robotic arms, these bearings facilitate smooth and precise movement, essential for tasks requiring high accuracy.

- Medical Equipment: CRB and CRBC bearings are often used in surgical instruments and imaging devices, where reliability and precision are paramount.

- Industrial Machinery: They play a crucial role in machinery that requires high load capacity and durability, such as lathes and milling machines.

- Aerospace: In aerospace applications, these bearings are used in control surfaces and landing gear, where performance and safety are critical.

Advantages of CRB and CRBC Series

The CRB and CRBC series offer several advantages that differentiate them from other bearing types:

– High Load Capacity: The cross roller configuration allows them to bear radial, axial, and moment loads simultaneously, making them incredibly versatile.

– Space Efficiency: The compact design is ideal for applications with limited space, optimizing the layout of equipment without compromising performance.

– Long Service Life: Enhanced durability means reduced maintenance costs and a longer lifespan, which is crucial in industrial applications.

– Precision Motion: The low starting friction ensures smooth motion with minimal wear, resulting in higher accuracy and efficiency.

Common Models of CRB and CRBC Series

When selecting a cross roller bearing, it is essential to choose the appropriate model to meet the specific requirements of your application. Some commonly used models include:

- CRB2008: This model is widely used in compact robotic applications, providing high load capacity in a small footprint.

- CRB2516: Known for its versatility, this bearing is suitable for both industrial machinery and precision tools.

- CRBC1008: With an integrated inner ring, this model is often favored in applications requiring quick assembly and minimal space.

- CRBC2010: This model excels in high-precision applications, making it ideal for medical and aerospace devices.

Conclusion

The CRB and CRBC series of cross roller bearings exemplify the blend of innovation and engineering excellence. Their unique features allow them to thrive in demanding environments, enhancing the performance of various machines and equipment across multiple industries. As technology continues to evolve, the role of these bearings will only become more critical, underpinning the advancements in automation, precision, and reliability. Understanding their characteristics, applications, and advantages will enable engineers and manufacturers to make informed decisions in bearing selection, ultimately leading to enhanced operational efficiency and longevity.